전체 관형 리벳

As one of professional high quality Full Tubular Rivets manufacturer, you can rest assured to buy Full Tubular Rivets from Notin and we will offer you the best after-sale service and timely delivery.

Full tubular rivets are also called as hollow rivets or tubular rivets, they are a common mechanical fastener, primarily used in applications requiring lightweighting or ventilation. Their structural characteristics are a completely hollow center with heads at each end, achieving connection through plastic deformation. Widely used in electronics, automotive manufacturing, aerospace, and other fields, they are favored for their unique structural design.

What is a hollow rivet?

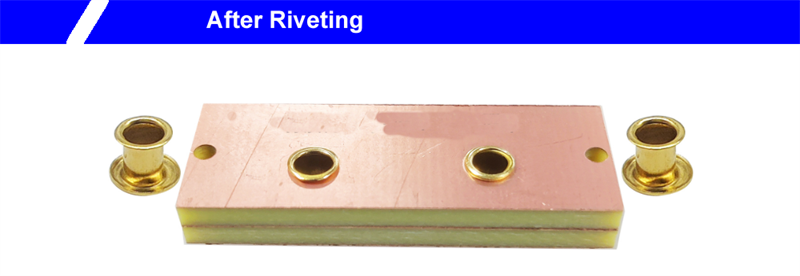

A full tubular rivet consists of a shank and a head. The shank has a through hole in the center, and the head is typically round or oval. During installation, the rivet is inserted through the materials to be joined, and the tail is expanded using a specialized tool to form another head, securing the materials together. Because of the hollow center, full tubular rivets maintain ventilation or fluid conduction after connection, which is their primary difference from solid rivets.

What materials can full tubular rivets be made of? What are the characteristics of different materials?

full tubular rivets are made from a variety of materials, with aluminum alloy, stainless steel, and copper being common.

Aluminum tubular rivets are lightweight and corrosion-resistant, making them suitable for electronic products and lightweight structures. They are the most cost-effective rivets.

Stainless steel tubular rivets are strong and heat-resistant, and are often used in automobiles and industrial equipment. They are more expensive than aluminum hollow rivets.

Brass tubular rivets or copper tubular rivets have good conductivity and are mostly used for electrical connections. Their disadvantage is that they are relatively expensive.

When selecting materials, factors such as the use environment, stress conditions, and cost should be considered.

Installation method of full tubular rivets

Special tools are required to install hollow rivets, such as manual riveting machines or fully automatic assembly machines.

The operation steps are as follows:

(1) Drill a hole in the material to be connected, with the hole diameter slightly larger than the rivet diameter.

(2) Insert the rivet into the hole, ensuring that the head is close to the surface of the material.

(3) Align the rivet hole with the matching punch (the punch is installed on the riveting machine). (4) Shake the riveting machine so that the tail of the rivet is impacted by external force and curls up, forming the same arc as the head, thereby achieving the fastening function.

Advantages of Full Tubular Rivets

(1) Light weight: The hollow structure reduces the amount of material used and is suitable for weight-sensitive applications.

(2) Good air permeability: The through hole in the middle can be used for ventilation or diversion to avoid sealing problems.

(3) Easy installation: Only one-side operation is required, which is suitable for narrow spaces or occasions where the back cannot be accessed.

(4) Low cost: Compared with welding or bolting, the riveting process is simple, saving time and manpower.

Disadvantages of Full Tubular Rivets

(1) Limited strength: The hollow structure leads to weak tensile and shear resistance, which is not suitable for high-load scenarios.

(2) Non-removable: Once installed, the rivet is usually not reusable, and disassembly will damage the connection.

(3) Requirements for material thickness: Materials that are too thin or too thick may affect the riveting effect.

What are the main applications of hollow rivets?

(1) Electronic products: such as computer cases, radiators, etc., taking advantage of their lightweight and air permeability.

(2) Automotive manufacturing: used for non-load-bearing parts such as interior panels and wiring harness fixings.

(3) Aerospace: reduce weight while meeting some ventilation needs.

(4) Furniture assembly: connect metal or plastic parts and simplify the installation process.

Comparison between hollow rivets and other rivets

(1) Compared with solid rivets: full tubular rivets are lighter and breathable, but have lower strength.

(2) Compared with semi-tubular rivets: the tail of semi-tubular rivets is partially hollow, with slightly higher strength, but the ventilation is not as good as full hollow rivets.

(3) Compared with blind rivets: the mandrel of blind rivets remains after installation, while the mandrel of full hollow rivets is completely detached, making the connection neater.

Suggestions for purchasing full tubular rivets

(1) Select rivets of appropriate length according to the thickness of the material to ensure that they can fully expand after installation.

(2) Consider the use environment. For example, corrosion-resistant or high-temperature resistant materials should be selected for humid or high-temperature conditions.

(3) Before purchasing in bulk, you can try it out first to confirm the riveting effect and tool compatibility.

Maintenance and precautions for full tubular rivets

(1) Avoid excessive force during installation to prevent rivet deformation or material damage.

(2) Regularly check the connection parts and replace them in time if they are loose or rusted.

(3) Keep them away from moisture during storage to prevent oxidation of the rivet surface that affects their use.

As a practical connector, full tubular rivets have irreplaceable advantages in specific scenarios. Understanding their characteristics and application methods will help you choose and use them reasonably in actual work, improving work efficiency and connection quality.

- View as

알루미늄 관형 리벳

알루미늄 관형 리벳은 다양한 제조 및 조립 공정에서 신뢰할 수 있는 부품으로, 내구성 있는 조인트를 만들기 위한 효율적이고 효과적인 솔루션을 제공합니다. Nuote Metals는 중국의 튜브 리벳 전문 제조업체입니다. 관형 리벳을 찾고 계십니까? RFQ를 원하시면 언제든지 저희에게 연락해 주세요.

더 읽어보기문의 보내기스테인레스 스틸 관형 리벳

Nuote Metals로 만든 스테인레스 스틸 관형 리벳은 금속, 플라스틱 및 복합 어셈블리로 내구성있는 연결을 보장하도록 설계되었습니다. Nuote Metals는 생크 직경 2.0mm ~ 10mm의 스테인레스 스틸 중공 리벳을 제공하며 응용 프로그램에 따라 두께와 길이가 다를 수 있습니다.

더 읽어보기문의 보내기