반 관형 리벳

You can purchase Semi Tubular Rivets from Notin with confidence, as we are a proficient producer of high-quality Semi Tubular Rivets. We promise to provide you with the best after-sale service and prompt delivery.

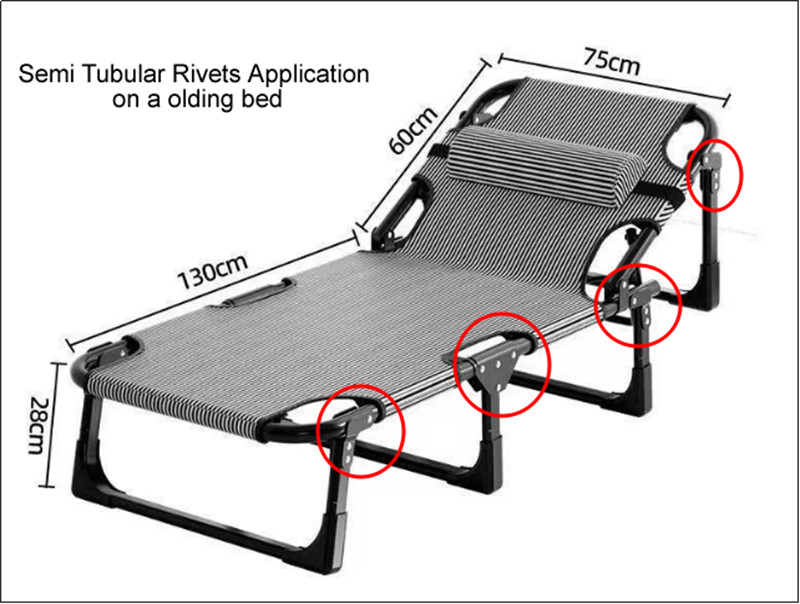

Semi-tubular rivets are a common mechanical fastener widely used in industrial manufacturing, electronic equipment, automotive parts, and other fields. Their structure lies somewhere between solid and hollow rivets, with a solid head and a hollow tail, combining the advantages of both. The following analyzes the characteristics of semi-tubular rivets and their differences from other rivets from various perspectives.

What are semi-tubular rivets?

Semi-tubular rivets typically have a solid cylindrical or round head and a hollow tubular tail. During installation, pressure is applied to the tail using a riveting tool, causing it to curl outward and form a secure locking structure. This process requires no pre-tapping or welding, making it suitable for quick assembly. In contrast, solid rivets require greater pressure to deform, while fully hollow rivets (such as blind rivets) rely on the mandrel to break to secure, requiring higher material strength.

What head shapes are available for semi-tubular rivets?

Semi-tubular rivet head shapes generally include flat heads (flat heads, suitable for applications requiring smooth surfaces), domed heads (semi-circular heads, aesthetically pleasing and practical, commonly used in construction, automotive, and other fields), countersunk heads (heads embedded within the material, suitable for applications requiring concealed connections), and large flat heads. Different head shapes can be selected based on your needs.

Materials and Strength of Semi-tubular Rivets

Common materials for semi-tubular rivets include aluminum, copper, steel, and stainless steel. Aluminum rivets are lightweight and corrosion-resistant, making them suitable for electronic devices; steel rivets are stronger and are often used in load-bearing structures. Compared to solid rivets, semi-tubular rivets are lighter but have slightly lower shear strength. Compared to full tubular rivets, their curled tails provide a larger contact area, resulting in a more stable connection.

What are semi tubular rivets primarily used for?

Typical uses for semi-tubular rivets include:

-Automotive manufacturing: securing interior panels or wiring harness brackets to prevent loosening under vibration.

-Home appliance assembly: connecting metal casings to prevent deformation caused by welding. -Hardware Tools: Assemble movable parts such as pliers and scissors, ensuring a balance between flexibility and durability.

Semi Tubular Rivet Installation Cost

Semi-tubular rivets can be installed with a standard rivet gun or punch, and can be operated by a single person. They are faster than welding or bolting. For example, the cost per aluminum rivet is approximately 0.05-0.3 RMB, which is lower than stainless steel bolts but higher than ordinary blind rivets. Their advantage is that they require no maintenance over long-term use, eliminating the need for anti-loosening washers or regular tightening.

Limitations of Semi Tubular Rivets

The main disadvantages of semi-tubular rivets are:

-Difficulty in Disassembly: Once a joint is established, it requires multiple drilling and destruction methods to remove it.

-Thickness Limitation: The total thickness of the joined materials is generally no more than twice the length of the hollow portion of the rivet.

-Surface Treatment Requirements: For outdoor use, choose galvanized or stainless steel to prevent rust.

Comparison with Other Fasteners

-Bolts and Nuts: They are removable and have a higher load-bearing capacity, but require access from both sides and are more expensive. - Welding: Excellent connection strength, but thermal deformation may affect precision, and it's not suitable for materials like aluminum and copper.

- Adhesives: No mechanical stress, but poor high-temperature resistance and aging resistance.

In summary, semi-tubular rivets strike a balance between lightweight, easy installation, and cost, making them particularly suitable for specialized connections with medium loads. When selecting a rivet, consider material compatibility, environmental conditions, and load-bearing requirements to ensure a suitable match.

- View as

황동 세미 중공 리벳

Nuote Metals에서는 황동 반중공 리벳 제조에 중점을 두고 있습니다. 당사의 리벳은 주로 구리-아연 혼합물인 H65 황동을 사용하며, 이는 견고한 내식성과 함께 뛰어난 전기 및 열 전도성을 제공합니다. 이 소재는 냉간압조 및 리벳팅 공정에 적합할 만큼 충분히 단단하고 유연합니다. 게다가 황동은 자연스러운 황금색을 띠기 때문에 장식용으로 사용하는 경우 추가 도금이 필요하지 않은 경우가 많습니다.

더 읽어보기문의 보내기팬 헤드 반중공 리벳

팬 헤드 반중공 리벳이 어떻게 만들어지는지 궁금하신가요? 다음은 간단한 안내입니다.

먼저, 올바른 금속 와이어를 골라 필요한 정확한 길이로 자릅니다. 그런 다음 콜드 헤딩 기계로 이동하여 와이어를 기본 리벳 모양으로 펀칭하고 형성합니다. 팬 헤드와 중공 생크가 실제로 형성되는 곳입니다. 다음은 열처리입니다. 우리는 모든 리벳이 적절한 강도와 인성을 갖도록 재료에 따라 시간과 온도를 조정합니다. 그 다음에는 녹을 방지하고 더 오래 사용할 수 있도록 아연도금이나 부동태화 등의 보호 마감 처리를 추가하는 경우가 많습니다. 그리고 우리는 최종 점검을 절대로 건너뛰지 않습니다. 각 배치를 검토하여 크기, 마감 및 성능이 표준에 맞는지 확인합니다.

우리는 항상 고객에게 주변을 안내해 드리는 것을 기쁘게 생각합니다. 해당 지역에 계시다면 알려주시면 투어를 준비해 드리겠습니다!

버섯머리 반중공 리벳

버섯머리 반구형 리벳은 부분적으로 속이 빈 생크와 결합된 버섯 뚜껑처럼 보이는 독특한 돔 모양의 머리에서 그 이름을 얻었습니다. 이 디자인은 설치 중에 리벳 모양이 저절로 형성되도록 하여 강력한 고정력을 제공하므로 멋진 외관과 견고한 성능이 모두 필요한 용도에 적합합니다. 설정하면 속이 빈 끝 부분이 벌어지고 단단히 고정되며 생크의 머리 부분과 상단 부분은 견고하게 유지되어 추가적인 지지력을 제공합니다.

더 읽어보기문의 보내기철 하프 관형 리벳

철제 반관형 리벳은 속이 빈 꼬리가 있는 기계식 커넥터입니다. 빈 부분을 압착하고 바깥쪽으로 플랜징하여 영구적인 스냅온 고정을 만드는 방식으로 작동합니다. 핵심 응용분야는 의류, 신발, 여행가방 등 경공업에 집중되어 있습니다. 연선 소재를 사용하면 리벳 접합 시 균열이 발생하는 것을 방지하고 비용상의 이점을 얻을 수 있습니다. Nuote Metals는 철제 반관형 리벳 전문 제조업체입니다. 우리의 리벳은 고품질이며 고객 만족을 보장하기 위해 하나하나 철저한 검사를 거칩니다.

더 읽어보기문의 보내기접시 머리 세미 중공 리벳

다른 연결 방법 대신 접시머리 반중공 리벳을 선택하는 이유는 무엇입니까? 이는 주로 고유한 장점 때문입니다. 설치 후 헤드는 표면과 같은 높이가 되어 돌출로 인한 잠재적인 간섭이나 안전 위험을 방지합니다. 반중공 설계로 인해 리벳팅 공정이 상대적으로 단순해지고 복잡한 장비가 필요하지 않습니다. 일반적으로 수동으로 또는 공압 도구를 사용하여 완료할 수 있습니다. 이 유형의 리벳은 다양한 두께의 재료에 적합하며 리벳팅 힘을 조정하여 다양한 상황에 적용할 수 있습니다.

더 읽어보기문의 보내기플랫 헤드 반중공 리벳

리벳팅은 산업 제조 및 일상적인 유지 관리에서 두 개 이상의 구성 요소를 함께 고정하는 일반적인 방법입니다. 플랫 헤드 반중공 리벳은 리벳의 일종으로 독특한 디자인과 적용 장점을 제공합니다. Nuote Metals는 플랫 헤드 하프 할로우 리벳 전문 제조업체입니다. 당사는 중국 동관에 위치하고 있으며 표면처리 자원이 풍부하고 운송이 편리하여 리벳 생산원가를 절감하고 있습니다.

더 읽어보기문의 보내기