구멍

Notin a reputable manufacturer in China, is willing to offer you Eyelets. We promise to provide you with the best after-sale support and prompt delivery.

Eyelets are characterized by quick installation, stable performance, and high reliability. Compared to other fasteners, eyelets are significantly cheaper per unit and have a wide range of applications. They are similar with tubular rivets, but made from different technics and machines.Eyelets are made from deep drawn technics, and tubular rivets are made from tube.

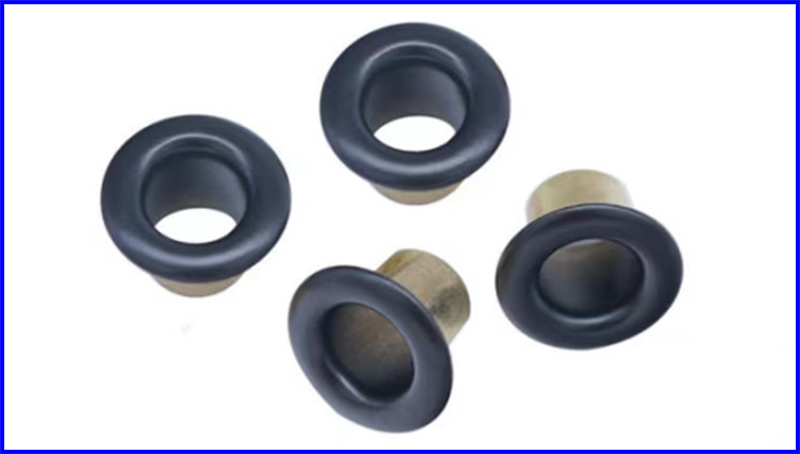

What is an eyelet?

An eyelet primarily consists of a cap and a shank. The cap is typically round or oval, offering a large surface area for easy hammering during installation. The shank is of moderate length and diameter, ensuring the rivet securely connects two or more components. The primary function of this type of eyelet is to connect and secure components, ensuring a secure connection without damaging the material.

What types of eyelets are there?

Based on the material used, they can be categorized as brass eyelets, steel eyelets, stainless steel eyelets, aluminum eyelets, and copper eyelets. Different eyelets have different characteristics depending on their material properties.

Brass eyelets: They offer excellent electrical conductivity and corrosion resistance, making them widely used in various electrical connections and fastening applications.

Steel eyelets: steel offers high strength and hardness, and are relatively inexpensive. However, steel has poor corrosion resistance and is prone to rusting, especially in humid environments. Therefore, the application range of iron eyelet rivets is relatively limited.

Stainless steel eyelets: Characterized by their strong corrosion resistance, they are often used for fastening food-grade products. However, due to the material's relatively high hardness, production is challenging, resulting in a relatively high unit price.

Aluminum eyelets: Used for fastening shoelace holes, belt holes, and windbreaker drawstrings, they allow for quick donning and doffing, while enhancing aesthetics.

Copper eyelets: Due to their excellent electrical conductivity, they are often used for connecting and securing electronic products.

What surface treatments are available for eyelets?

Eyelets are hot-dip galvanized and polished to create a protective layer on the surface that provides antistatic, corrosion-resistant, and anti-allergenic properties. Copper eyelets come in a variety of colors, including white nickel, polished tin, imitation gold, antique bronze, matte nickel, bronze, zinc, and silver.

Some customers also prefer to have the eyelet head powder coating to match their color with the overall design and prevent oxidation.

- View as

스테인리스 작은 구멍

우리는 중국 동관의 Nuote Metals입니다. 우리 공장에서는 다양한 산업 분야에 적합한 고품질 스테인레스 구멍을 만듭니다. 우리는 수년 동안 스테인레스 구멍을 생산해 왔습니다. 좋은 스테인레스 소재를 사용하고 있습니다. 이 소재는 스테인레스 구멍을 튼튼하고 녹슬지 않게 만듭니다. 우리는 다양한 크기의 스테인레스 구멍을 만듭니다. 일부는 전자 제품의 경우 작습니다. 일부는 아웃도어 제품에 적합합니다. 모든 스테인레스 구멍은 직원이 점검합니다. 그들은 각 조각을 주의 깊게 살펴봅니다. 많은 고객이 잘 작동하고 오래 지속된다는 이유로 스테인레스 구멍을 선택합니다. 새로운 프로젝트를 위해 샘플을 빠르게 만들 수 있습니다.

더 읽어보기문의 보내기작은 구멍과 세탁기

많은 일상용품에서 구멍과 와셔를 찾을 수 있습니다. 그것들은 작은 금속 부품입니다. 구멍은 작은 고리 모양이고 와셔는 평평한 디스크입니다. 직물이나 플라스틱과 같은 재료에 강력하고 부드러운 구멍을 만들기 위해 함께 눌러집니다. 이렇게 하면 재료가 찢어지는 것을 방지할 수 있습니다. 중국에서는 Nuote Metals가 작지만 유용한 부품을 만듭니다. 우리는 다양한 작업에 맞는 다양한 유형의 구멍과 와셔를 생산합니다.

더 읽어보기문의 보내기What are the main applications for eyelets?

Eyelet rivets are widely used in the construction, automotive, marine, aviation, and electronics industries.

In the construction industry, eyelet rivets are used to connect various metal components, such as steel beams and columns.

In the automotive, marine, and aviation industries, eyelet rivets are used to connect various materials, such as aluminum alloys and titanium alloys.

In the electronics industry, eyelet rivets are used to connect various metal and non-metallic materials, such as metal plates and plastic sheets.

What tools are used to rivet eyelets?

Eyelet rivets can be riveted using either manual or electric riveting pliers. Manual riveting pliers are a common tool and are generally suitable for riveting small eyelets. Electric riveting pliers are suitable for riveting large eyelets and large quantities.

What preparations are required before riveting?

Preparation before riveting includes cleaning the surface of the material being riveted and selecting the appropriate rivet hole diameter. Cleaning the surface of the material being riveted removes surface dirt and grease, ensuring a secure joint. Selecting the appropriate rivet hole diameter can prevent cracking or loosening during riveting.

What precautions should be taken when riveting?

1. The installation position of the eyelet rivet must coincide with the centerline of the rivet hole.

2. The eyelets shank should be perpendicular to the surface of the material being riveted during riveting.

3. The eyelet head must remain horizontally stable.

4. The depth of the eyelet hole should be equal to the sum of the rivet shank length and the length of the eyelet pressure riveting portion.

5. The riveting force should be appropriate, neither too high nor too low, depending on the thickness and properties of the material.

6. After riveting, the eyelets quality should be inspected for signs of broken eyelets or foreign matter.

Conclusion

Eyelet rivets are a versatile rivet fastener that can be widely used to connect various metal sheets and dissimilar materials. Thorough preparation is required before riveting, including selecting the appropriate rivet hole diameter and cleaning the surface of the material being riveted. During riveting, factors such as the riveting force and hole depth should be carefully considered to ensure a high-quality connection.